Envisioning a Repair Society Within a Circular Economy

October 1, 2020

Dr. Jennifer Russell, Department of Sustainable Biomaterials at Virginia Tech, has been working with a team of researchers from Lund University, in Sweden, to amass knowledge from around the world about the best policies and practices for optimizing repair systems for e-devices as part of moving our society towards becoming a Circular Economy. Funded by the Swedish Research Council for Sustainable Development (FORMAS), this 2-year project is entitled "Creating a Repair Society - Policies, Networks, and People" or "CREACE."

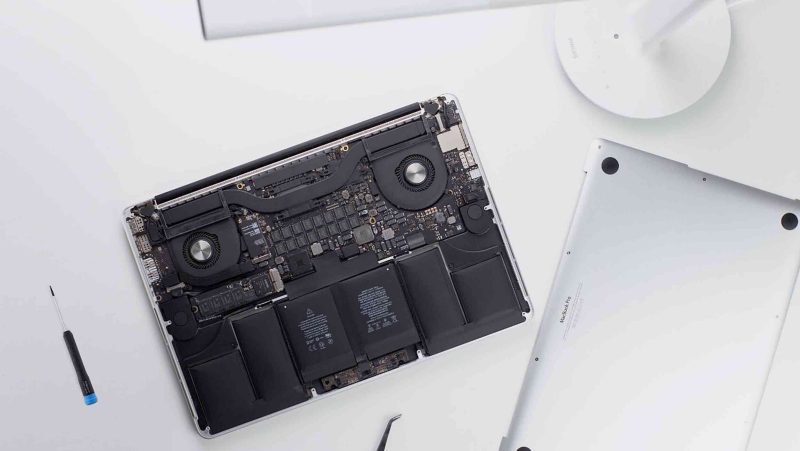

E-waste is one of the fastest growing waste streams globally as the devices we use to connect with the world can break down or become obsolete. Despite some success at recycling e-waste in the U.S. and Sweden, there is little known about the state of the repair markets for these products before they enter the waste stream, or how to better climb the waste hierarchy and retain greater material value. Compounding this challenge is the fact that the context for a Circular Economy is very different in the USA. While many lessons can be learned from Sweden and the broader European Union's approach to Circular Economy, Dr. Russell believes that a different 'toolkit' of strategies and practices may be needed before North American companies and communities will readily adopt Circular Economy practices.

Through a series of US-based case studies, Dr. Russell's contributions to this project include the identification of behavioral, economic, technological, and policy barriers to increased repair activities. In collaboration with iFixit, a US-based advocate for the Right to Repair movement, Dr. Russell's research focuses on the identification of best practices for enabling the repair of electronics and appliances in North American markets. The Right to Repair movement encompasses activities and legislation designed to ensure that Original Manufacturer and/or brand owner companies provide the information, tools, and spare parts for their e-devices making them more easily repairable by product owners and independent repairers. By prioritizing repair capabilities, over and before recycling, product life-cycles can be extended, helping to move us towards becoming a Repair Society. Significantly greater economic, social, and environmental benefits can be achieved by adopting these types of Circular Economy best practices.

Some preliminary findings regarding the legal and policy barriers to repair, as well as historical and cultural perspectives on repair, were presented at the first International Society for Circular Economy 2020 Conference in June.

You can find more information, and monthly blog updates at the CREACE Project website.